It’s not often these days that I make a breakthrough rather than a series of small adjustments in improving my lino cut. This breakthrough is so modest, simple and, now I think about it, so embarrassingly obvious that I am pretty sure most people do it already: it’s to sand the lino before using it. Give lino a very gentle sanding with a fine paper, I use the black wet/dry 600 (dry), and printing large areas of perfectly smooth thin, thin ink becomes a doddle.

Thin, thin ink is rather important for my kind of printing: I usually go to six or seven layers of colour and because I use my dip pen drawings as my pattern to cut, there’s usually a lot of very fine detail. The gloopier the ink, the more detail goes and the messier everything gets. My friend and fine printmaker Ian Phillips mentioned the business of sanding as a throwaway comment and he’s changed my life. Well, not my life; the house still needs cleaning and there’s no masseur available on tap, but it has improved my printing no end.

The other bit of preparation I find helps is to rub a bit of colour into the lino: cutting through a colour (I usually use red) into grey is so much easier than grey on grey and somehow much more satisfactory.

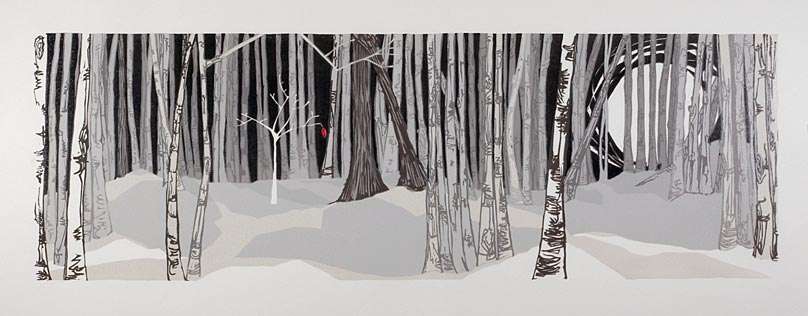

The print here is inspired by a poem by Carol Ann Duffy about Red Riding Hood. The connection is loose to say the least, I’m taking part in an exhibition for World Book Day next year and this is a possible entry. As you can see it is layer on layer and registration is critical. I also use cobalt dryers to speed up the drying of my now exquisitely thin ink layers. Cobalt dryer is a pretty purple liquid which I add in tiny drops to the inks (it doesn’t affect colour at all) and instead of my waiting around for days between layers, I have only to hop from one foot to the other for a few hours before I’m printing again.

Words to the wise about this sanding business though – do try and remember to do it before you do the master drawing on the lino block. I was in peril of scraping off all my pen lines on this one…

Hi Laura..thankyou so much for your very helpful videos…I have just started cutting lino and have hit a printing hitch that I hope you could help me with. I am getting very patchy areas of ink in the larger flat sections, well all over really. I have tried double inking, lots of rubbing etc, but nothing improves it. The materials I am using are…

Green soft cut lino (unknown make- came in a starter set)

Schminche Aqua inks

Fabriano 240gsm paper – patching seems to also happen on lighter papers

Your advice would be greatly appreciated!

Hi I am sorry but I can’t advise without being there and seeing what you are doing. Can I suggest you go to the manufacturer and ask about the ink or to your supplier – they are usually very good with technical help like this.

Hiya. As Laura says, it’s hard to know without being there and seeing the issue. I sometimes get patchy areas with Fabriano papers if they’re too textured. And if a brayer is too hard and doesn’t distribute the ink evenly. Sanding the block, as the article says, may help with this issue.